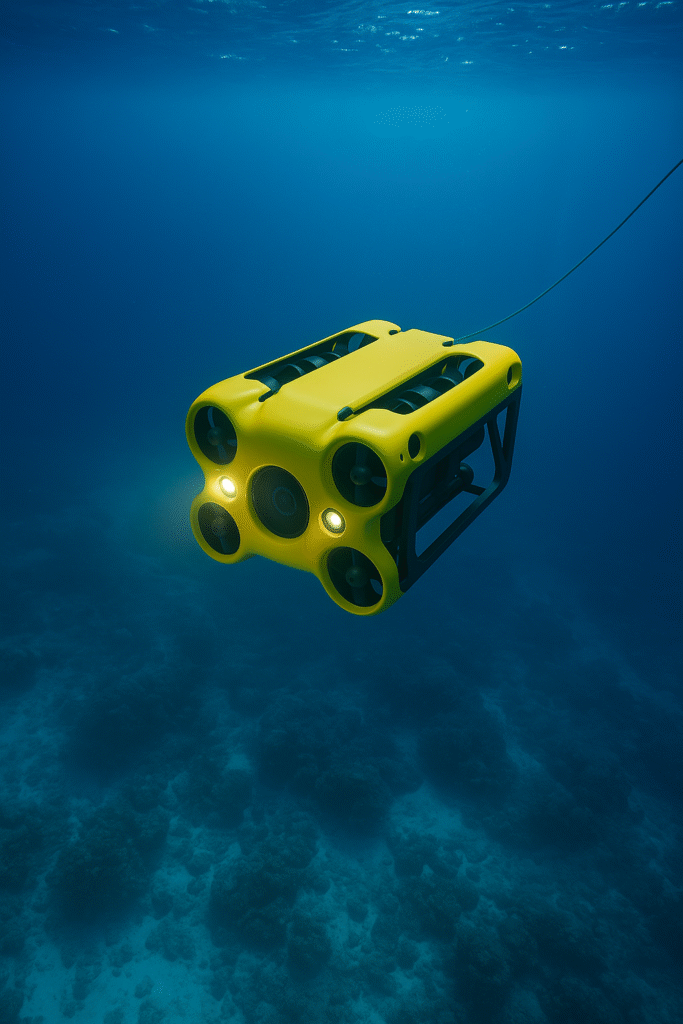

Subsea Pipeline & Infrastructure Inspection

Equipped with ultra-HD optical cameras, LED floodlights, and 360° navigation control, the Deep-X2™ excels in detailed scanning and documentation of pipelines, risers, and wellheads.

Real-time image transmission with AI-enhanced clarity.

Adaptive hovering & tracking over long distances.

Non-intrusive inspection with zero-contact stability control.

Ideal for oil & gas operators, offshore contractors, and marine geoscience missions.

Precision Manipulation at Depth

The Deep-X2™ features an advanced robotic manipulator arm, enabling operators to perform intricate tasks in harsh subsea conditions. Whether it’s turning subsea valves, collecting specimens, or interacting with pipeline structures, the manipulator ensures pinpoint precision and reliability under extreme pressure.

Compact, corrosion-resistant design.

High-torque performance for mechanical intervention.

Synchronized with operator joystick or autonomous routines.

Engineered for control. Designed for action.

Introducing SABA Deep-X2™ Redefining Subsea Inspection Excellence

Designed, engineered, and proudly developed by SABA Drilling, the Deep-X2™ is a next-generation Remotely Operated Vehicle (ROV) purpose-built for extreme underwater inspection, maintenance, and intervention tasks across the oil & gas, offshore wind, and subsea infrastructure sectors.

Key Features & Advantages:

🔸Precision Visual System:

Equipped with an ultra-HD 12K central optical camera plus dual side lenses for wide-angle and low-light operations. Real-time video streaming and recording provide unparalleled visibility in deep-sea environments.

🔸Depth Rating:

Engineered to perform at depths of up to 3,200 meters, Deep-X2™ handles high-pressure zones with confidence.

🔸Extended Dive Time:

Thanks to its modular high-capacity power pack and efficient thermal regulation, Deep-X2™ operates continuously up to 16 hours on mission.

🔸Adaptive Maneuverability:

A quad-thruster propulsion system ensures exceptional horizontal, vertical, and rotational movement allowing Deep-X2™ to navigate complex structures like risers, pipelines, BOPs, and subsea trees with ease.

🔸Tethered Control + Autonomous Mode:

Operable via advanced tether control unit with AI-assisted stability, or semi-autonomous navigation for pre-defined missions.

🔸Manipulator Arm (Optional Module):

Designed for underwater object retrieval, valve turning, and interaction with subsea assets.

🔸Durability & Safety:

Constructed from marine-grade anodized aluminum with shock-resistant housing, ensuring longevity and resistance to corrosion, impact, and deep-sea stress.

Deep-X2™ Precision Beneath Pressure

Developed and engineered by SABA’s elite innovation team, Deep-X2™ represents the next generation of subsea remotely operated vehicles (ROVs), built to endure extreme underwater environments and deliver critical performance when it matters most.

With its high-performance composite frame, ultra-efficient 6-thruster propulsion system, and advanced AI-assisted navigation, Deep-X2™ provides unmatched agility and precision during deep-sea inspections, repairs, and monitoring operations.

Equipped with 12K ultra-resolution optical + infrared cameras, an adaptive lighting array, and a fully integrated real-time telemetry and control interface, Deep-X2™ enables mission-critical decision-making even in zero-visibility conditions.

Certified for depths up to 3,200 meters, and pressure-tested to exceed industry thresholds, this vehicle is the perfect solution for offshore platforms, pipeline surveys, subsea infrastructure diagnostics, and emergency response operations.

Built by SABA. Trusted by the Deep.

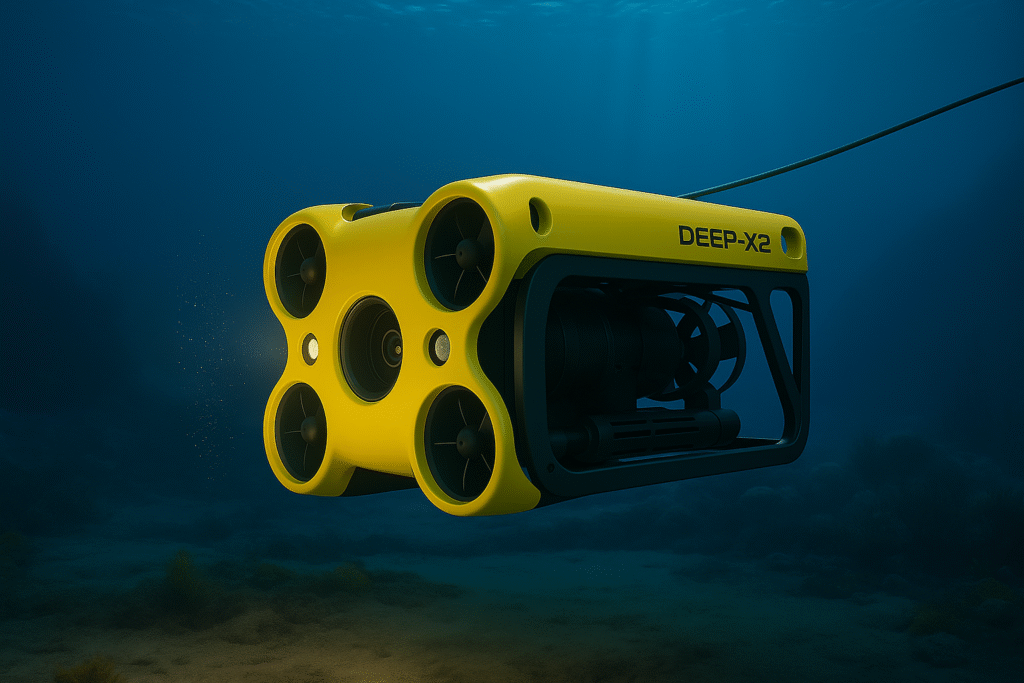

Advanced Subsea Surveillance with Deep-X2™

The Deep-X2™ is a next-generation Remotely Operated Vehicle (ROV) engineered for high-precision subsea inspection, maintenance, and intervention. Shown here conducting a detailed visual assessment of a blowout preventer (BOP), the Deep-X2™ provides unmatched situational awareness in ultra-deep environments.

Technical Construction:

🔸Chassis Material: Aerospace-grade anodized aluminum alloy with high-density polymer shielding.

🔸Pressure Rating: Certified to operate at depths exceeding 2,000 meters.

🔸Corrosion Resistance: Multi-layer marine coating for long-term durability in brine, sulfides, and chemical zones.

Primary Applications:

🔸Real-time BOP condition monitoring.

🔸Pipeline integrity assessment.

🔸Structural inspections of wellheads and risers.

🔸Pre-deployment site surveys and subsea asset mapping.

Smart Navigation & Control:

🔸6-axis stabilization system with dynamic thruster response.

🔸AI-assisted visual recognition for autonomous tracking.

🔸Tethered surface control + optional fiber-optic data uplink.

Built for resilience. Trusted for precision.

Deep-X2™ — where technology meets the ocean floor.

Advanced Subsea Engineering in Motion

Built with a reinforced carbon-composite chassis and engineered for maximum hydrodynamics, Deep-X2™ thrives in demanding subsea missions. Its multi-directional thruster system ensures fluid navigation around complex subsea structures, while the high-torque manipulator arm offers exceptional dexterity for precision intervention tasks.

Whether inspecting offshore platforms, recovering sensitive equipment, or navigating narrow subsea pipelines, Deep-X2™ executes with surgical precision and unmatched control.

Eyes in the Deep Precision, Redefined

At the core of Deep-X2™ is its 12K optical + IR dual-camera system, delivering unparalleled clarity in turbid or pitch-black waters. The front-facing array includes high-lumen LEDs with adaptive brightness, enabling safe and detailed inspections at depths exceeding 3,200 meters.

Designed for oil & gas asset inspections, pipeline diagnostics, marine biology surveys, and underwater archaeology, Deep-X2™ captures the unseen in high definition, and in real time.

about dEEP-X2

Confidence Beyond Purchase We’ve Got You Covered.

At SABA Drilling, every Deep-X2™ unit is backed by an industry-leading 24-month limited warranty, covering all manufacturing defects, sensor malfunctions, and electronic subsystem failures under normal operational use.

We also offer:

Extended Service Plans (up to 5 years) upon request

Global Repair & Maintenance Centers for rapid turnaround

Modular Design for fast on-site part replacements

Remote Diagnostic Support via encrypted connection

Annual Inspection & Recalibration Programs

Our highly trained technical team is available to support your operations 24/7. In the unlikely event of failure during a mission, we guarantee priority repair or unit replacement to minimize your downtime.

Deep-X2™ isn’t just a product. It’s a promise of durability, performance, and lifetime partnership.