Drill Collar – High-Strength Threaded Connection

Engineered for Precision and Durability

SABA Drilling’s premium-grade Drill Collars are manufactured from AISI 4145H-modified alloy steel or non-magnetic materials, heat-treated for exceptional mechanical properties and fatigue resistance. Each collar features precision-machined connections, including NC and REG threads, ensuring a secure and leak-proof link in your Bottom Hole Assembly (BHA). Our collars are ideal for high-angle and directional drilling, offering excellent weight-on-bit transmission, torque resistance, and performance reliability even in the most demanding downhole conditions.

API Spec 7-1 compliant

🔹 Hardbanding and spiral-groove options available

🔹 NDT-tested: UT, MPI, and thread inspection

🔹 Available in slick or spiral designs for differential sticking reduction

Boost your rig performance with drill collars designed to exceed operational standards.

In-stock and ready to ship worldwide.

Non-Magnetic Drill Collars – Ideal for MWD/LWD Applications

Zero Magnetic Interference. Maximum Control.

SABA Drilling offers high-precision Non-Magnetic Drill Collars made from premium-grade non-magnetic stainless steel, engineered to support Measurement While Drilling (MWD) and Logging While Drilling (LWD) operations. Our collars are crafted with superior concentricity and strict metallurgical control, ensuring no magnetic distortion and delivering accurate real-time data collection. Surface finish and mechanical tolerances are held to the highest international standards.

🔹Zero residual magnetism guaranteed

🔹Available in sizes 3-1/8” to 9-1/2” OD

🔹Precision threading with customized box & pin connections

🔹Recessed lift subs and slip areas optional

Your directional drilling partner in hostile and high-precision drilling environments.

Let SABA Drilling strengthen your bottom hole success with unmatched quality and service.

Drill Collar Specifications – Built to API Standards

At SABA Drilling, we supply a complete range of Drill Collars engineered and manufactured to meet or exceed API Spec 7-1 standards. These heavy-weight components are essential in delivering precise weight on bit (WOB), minimizing drill string vibration, and enhancing the stability of your bottom hole assembly.

Our drill collars are available in a variety of outer and inner diameters, connection types, and materials including AISI 4145H and non-magnetic steel for high-accuracy MWD/LWD operations. Precision-machined, heat-treated, and NDT-tested, they provide the durability and strength demanded by today’s high-performance drilling rigs.

🔹 Available in Spiral or Slick design.

🔹 API connections including NC26, NC31, NC38, NC50, and 6 5/8 Reg.

🔹 Non-magnetic options for directional drilling.

🔹 High-torque capacity and consistent performance under extreme load.

Optimize your drilling performance with drill collars engineered for precision, longevity, and global rig compatibility.

| OD (Outside Diameter) | ID (Inside Diameter) | Nominal Weight (lb/ft) | Grade | Connection Type | Length (ft) | Material | Tool Joint OD | Slip/Recess Area |

|---|---|---|---|---|---|---|---|---|

| 3 1/8" | 1 1/4" | 27.7 | AISI 4145H | NC26 | 31 (typical) | Non-magnetic / 4145H | 4 1/8" | Spiral or Plain |

| 3 1/2" | 1 1/4" | 33.85 | AISI 4145H | NC31 | 31 | Non-mag / Alloy Steel | 4 3/4" | Spiral or Plain |

| 4 1/8" | 1 3/4" | 52.6 | AISI 4145H | NC38 | 31 | Non-mag or 4145H | 5 1/2" | Spiral or Plain |

| 6 1/4" | 2 13/16" | 105 | AISI 4145H | NC50 | 31 | Non-mag / Steel | 7 5/8" | Spiral or Plain |

| 8" | 3" | 155 | AISI 4145H | 6 5/8 Reg | 31 | 4145H Modified | 9 1/4" | Spiral or Plain |

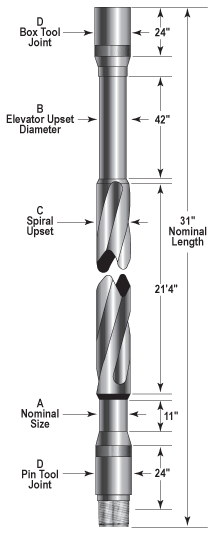

Spiral Groove Drill Collars Designed for Maximum Downhole Efficiency

Powerful Design. Proven Performance.

At SABA Drilling, we provide Spiral-Grooved Drill Collars engineered to reduce differential sticking and enhance fluid circulation during drilling operations. The helical grooves are precision-machined to minimize the contact surface between the collar and the borehole wall—significantly lowering the risk of stuck pipe incidents in high-angle and deep wells.

🔹 Optimized for high-deviation and extended reach wells.

🔹 Reduces pressure differential and improves mud flow.

🔹 Available in both magnetic and non-magnetic options.

🔹 Manufactured in accordance with API Spec 7-1 and DS-1 standards.

Boost safety, speed, and reliability with collars that are as smart as they are strong. Connect with SABA Drilling to secure top-tier BHA components backed by performance.

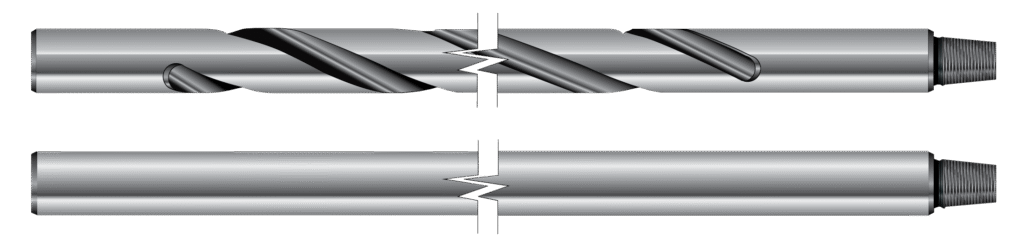

Precision Engineered Drill Collars Your BHA Foundation Starts Here

At SABA Drilling, we offer a complete portfolio of Drill Collars engineered for maximum efficiency, reliability, and compatibility with the most demanding drilling environments. Our collars are available in Slick and Spiral-Grooved designs, with options for standard recess, special ID recess, and non-magnetic execution—tailored to suit every well profile and operational requirement.

Each collar undergoes precision machining, ultrasonic testing (UT), and thread gauging to ensure strict compliance with API Spec 7-1, DS-1, and NS-2 inspection standards. Our engineering team works closely with operators to optimize weight-on-bit, torque transfer, and borehole stability.

🔹Minimized differential sticking

🔹Superior mechanical performance

🔹Optimized for both vertical and directional wells

Engineered Spiral Collars Precision in Every Groove

SABA Drilling’s Spiral-Grooved Drill Collars are more than just heavy-weight components they’re the foundation of intelligent downhole design. Featuring a high-grade protective finish and meticulously cut helical flutes, these collars reduce wall contact and fluid resistance, ensuring smoother, safer drilling through challenging formations.

🔹Corrosion-resistant finish for extended tool life.

🔹Spiral design reduces differential sticking and improves cuttings transport.

🔹Perfectly balanced for vertical, deviated, and horizontal wells.

🔹Globally supplied to top-tier operators in desert and offshore environments.

Where innovation meets rugged durability

Choose SABA Drilling to power your drilling success with the next generation of collar performance.