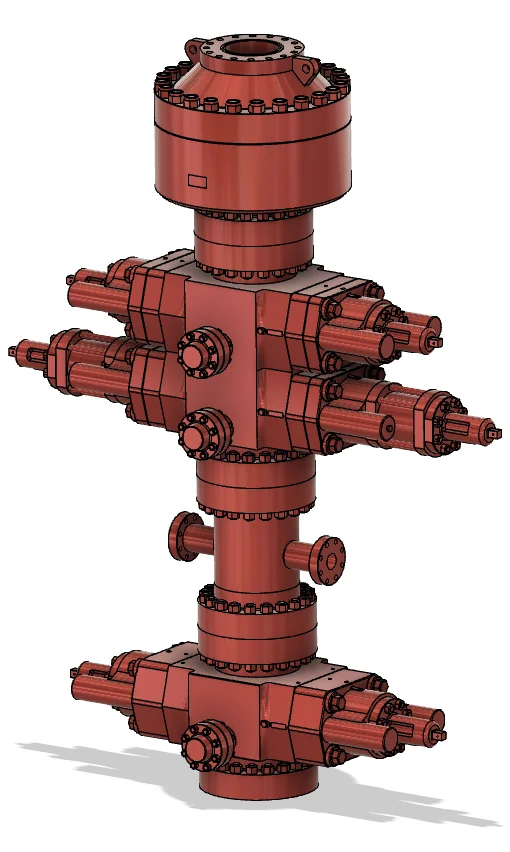

Ram BOP Solutions

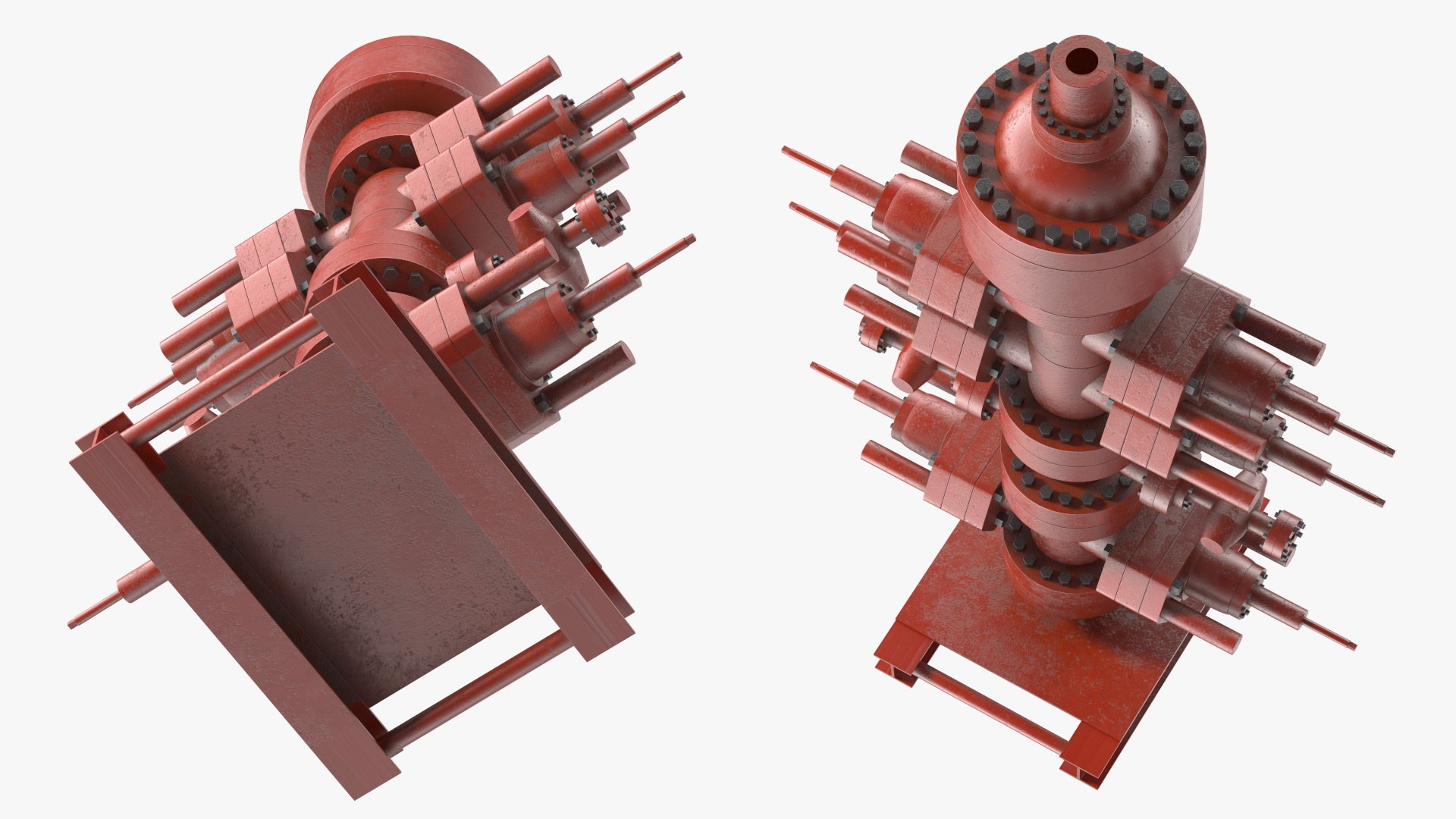

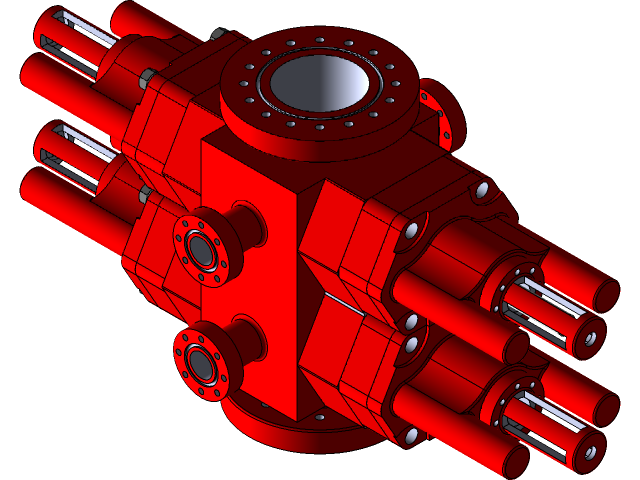

Engineered for maximum sealing performance, our Ram BOPs are API 16A certified and available in single, double, and quad configurations. Designed for safe and rapid shut-in across a wide range of bore sizes.

Annular BOP Systems

Versatile, robust, and ideal for stripping and sealing, our Annular BOPs handle up to 10,000 psi with precision elastomer control. Available for both surface and subsea drilling operations.

BOP Spare Parts & Service

From ram rubbers to bonnet seals, we supply all critical BOP spares with global shipping and rapid turnaround. Full traceability and compatibility with leading OEMs guaranteed.

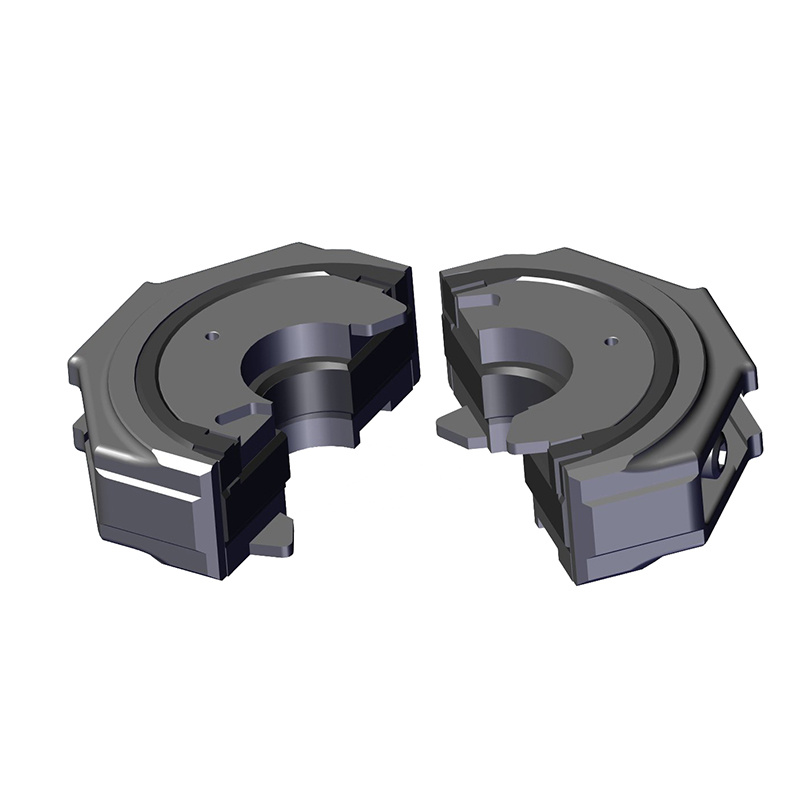

Complete Spare Parts Coverage for Blowout Preventers (BOP)

At SABA Drilling, we understand that operational integrity depends not just on complete systems—but on every component within. That’s why we offer a full inventory of certified spare parts for Ram-type BOPs, ready to ship worldwide to support your maintenance cycles and emergency repairs.

The table below outlines the most essential BOP components along with their functions and estimated quantities required per unit. Each part is engineered to meet or exceed API 16A standards and is backed by

🔸Ram Block Assemblies and Sealing Elements to ensure well control under extreme pressure.

🔸Bonnet Seals, Guide Bushings, and Wear Rings to maintain internal alignment and prevent leakage.

🔸Hydraulic Cylinders, Springs, and Piston Rods for smooth, reliable actuation.

🔸Seal Kits, Studs & Nuts, and Test Plugs for complete serviceability and periodic pressure testing.

Because in drilling operations, every part matters.

| Component | Description | Approximate Quantity per BOP |

|---|---|---|

| Ram Block Assembly | Main body that holds the sealing and shearing components | 2 |

| Ram Rubber (Sealing Element) | Elastomeric element for sealing pipe or bore | 2 |

| Bonnet Seal | O-ring or metal-to-metal seal for bonnet closure | 4 |

| Piston Rod | Connects piston movement to ram operation | 2 |

| Hydraulic Cylinder | Controls ram actuation under hydraulic pressure | 2 |

| Guide Bushing | Ensures correct alignment of moving parts | 2 |

| Locking Screw | Secures ram block in position during operation | 2 |

| Position Indicator | Mechanical or electronic status indicator for ram position | 2 |

| Spring (Return Type) | Provides return force after hydraulic actuation | 4 |

| Seal Kit | Full replacement kit for seals and gaskets | 1 |

| Wear Ring | Protects internal surfaces and guides piston travel | 2 |

| Bonnet Studs & Nuts | Secures bonnet to body, high-strength fasteners | 8 |

| Accumulator Hose Connection | High-pressure fitting for hydraulic control lines | 2 |

| Grease Fitting | Allows periodic lubrication of moving parts | 2 |

| Test Plug | Used for pressure testing of BOP cavity | 2 |

Supplier You Can Trust

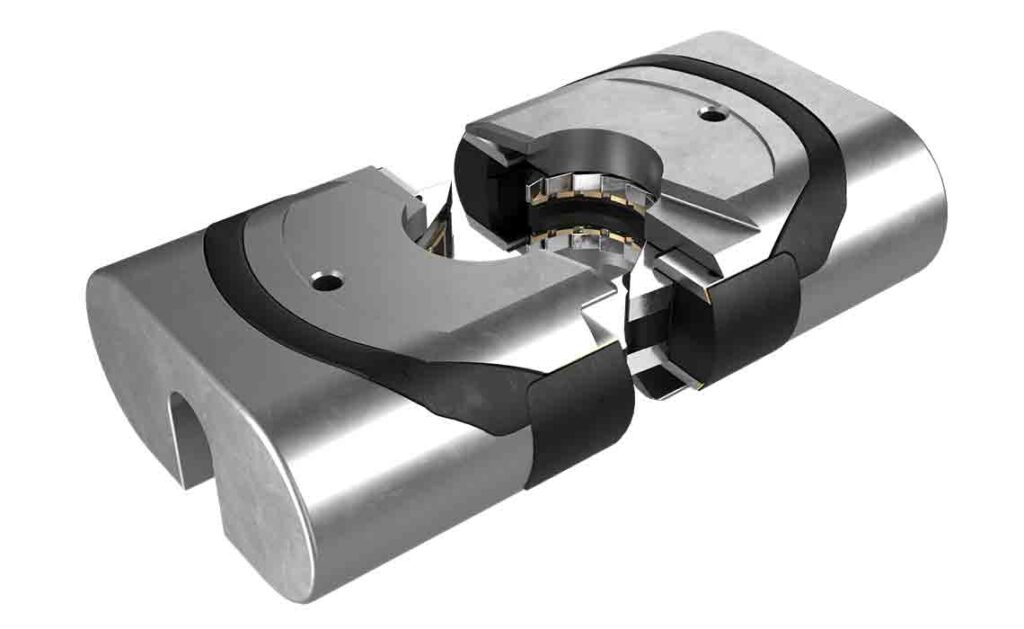

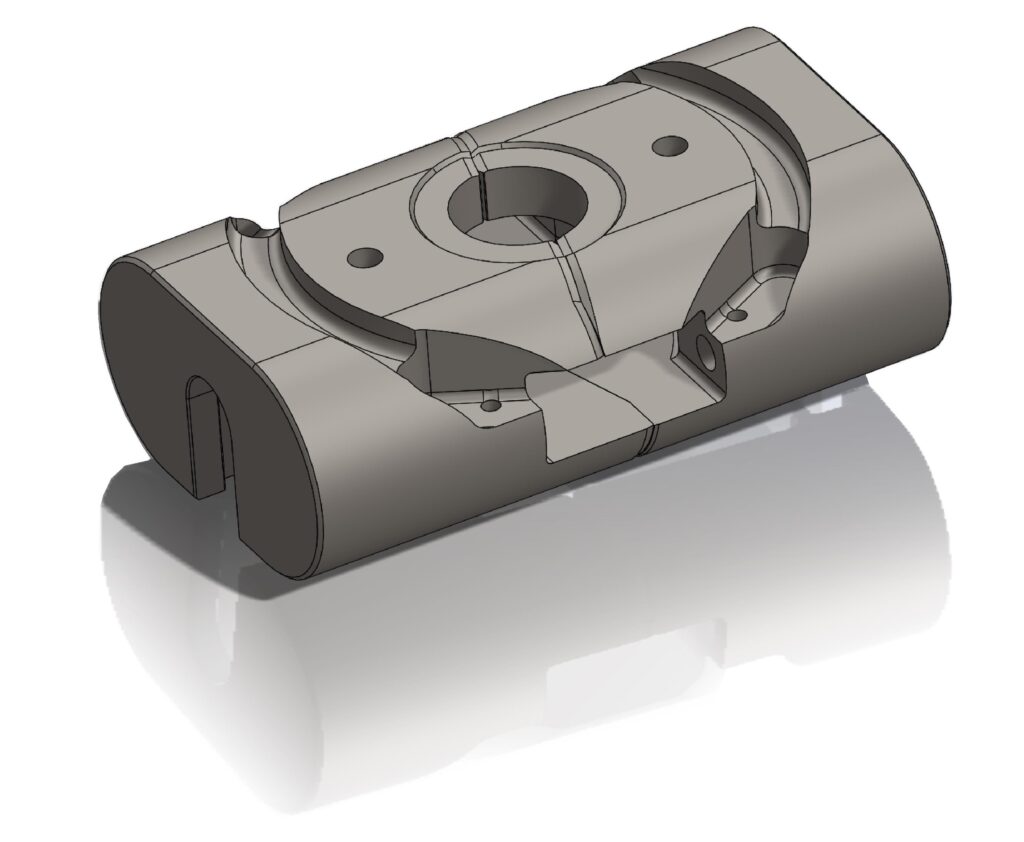

As an international supplier, we provide precision-engineered BOPs sourced from globally trusted manufacturers. Each unit we supply is backed by rigorous CAD modeling, FEA validation, and international standards to ensure maximum structural performance and operational integrity.

🔸3D-modeled geometry ensures exact ram alignment

🔸Finite Element Analysis (FEA) validated body design

🔸Optimized for stress concentration reduction and fatigue resistance

🔸Compliant with API 16A, 16C, and 16D standards

🔸Modular construction for multiple rig configurations

Field-Proven Performance. Globally Delivered.

We supply Ram BOPs that are trusted in the world’s most demanding drilling operations—from onshore rigs to offshore high-pressure wells. Every BOP is tested for pressure, reliability, and serviceability, and is delivered with full traceability and global support.

🔸High-strength forged steel construction with corrosion protection

🔸Quick-change ram system for reduced maintenance time

🔸Pressure-tested beyond rated working conditions

🔸Compatible with leading hydraulic control systems

🔸Fast delivery & international spare parts sourcing

| BOP Type | Typical Bore Sizes (inches) | Pressure Rating (psi) | Applications | Standards Compliance |

|---|---|---|---|---|

| Ram BOP – Single | 7-1/16" to 21-1/4" | 5,000 – 15,000 | Onshore / Offshore | API 16A |

| Ram BOP – Double | 7-1/16" to 21-1/4" | 5,000 – 15,000 | Onshore / Offshore | API 16A |

| Ram BOP – Quad | 13-5/8" to 21-1/4" | 10,000 – 15,000 | High-spec Offshore Rigs | API 16A |

| Annular BOP | 7-1/16" to 21-1/4" | 2,000 – 10,000 | Primary well sealing / stripping | API 16A / API 16D |

| Subsea BOP Stack | 13-5/8" to 18-3/4" | 10,000 – 15,000 | Deepwater Wells | API 16A / 16C / 16D |

| Surface BOP Stack | 11" to 21-1/4" | 5,000 – 15,000 | Land Rigs / Jack-up Platforms | API 16A / 16C |

Global Supply. Trusted Standards.

As a reliable international supplier, we specialize in sourcing and delivering high-performance Blowout Preventers (BOPs) and well control equipment for both onshore and offshore operations.

We collaborate with world-class manufacturers to ensure that every product we offer meets API standards and performs under pressure. From precision-engineered designs to fast global logistics we make sure you get the right equipment, right on time.

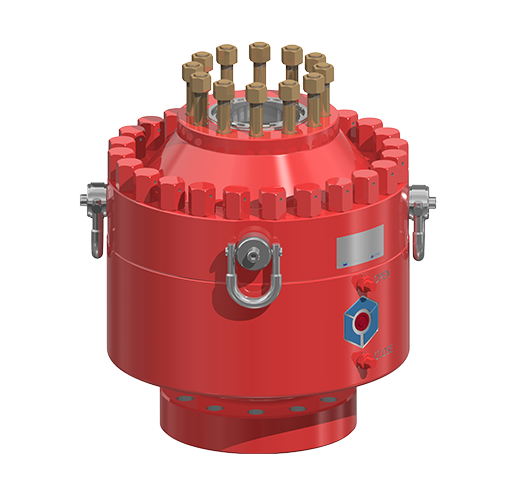

Annular BOPs – Versatile Sealing for Every Wellhead

As a trusted international supplier, we provide premium-grade Annular Blowout Preventers (BOPs) designed to ensure smooth well control operations in both land-based and offshore rigs. These BOPs use a donut-shaped elastomer that compresses uniformly around various pipe sizes—making them ideal for stripping, circulating, and emergency shut-ins.

🔸Handles variable pipe diameters with a single sealing element.

🔸Designed for pressures up to 10,000 psi.

🔸Compatible with API 16A and 16D hydraulic systems.

🔸Easy-to-maintain bonnet design for field servicing.

🔸Suitable for both surface and subsea stacks.

Delivering the flexibility your well control operations demand wherever you drill.

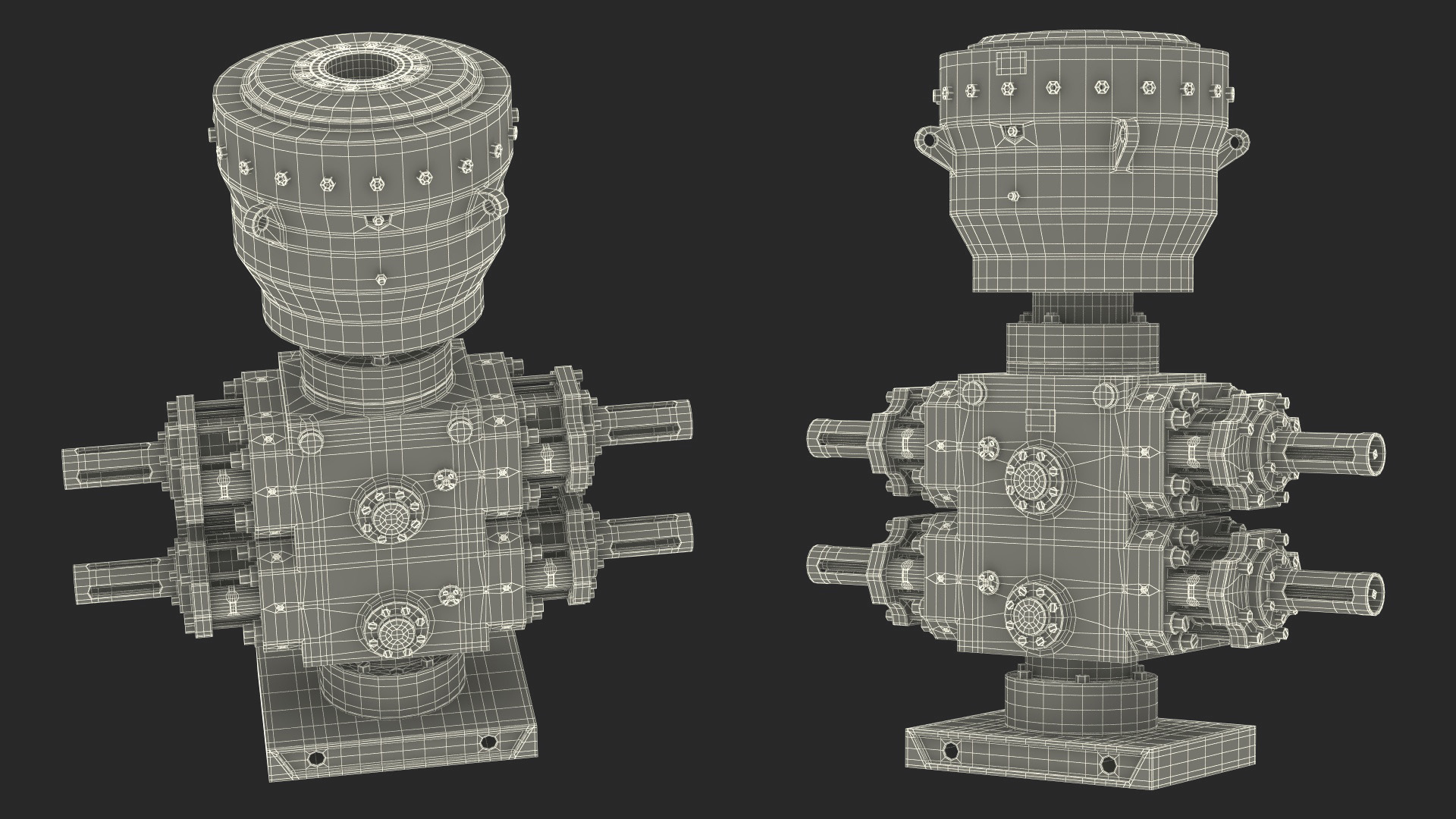

Total Well Control, Delivered Globally

At SABA Drilling, we proudly supply complete BOP stacks including both Annular and Ram Preventers engineered to perform under the highest well pressure and toughest drilling conditions.

Whether you’re operating onshore or offshore, our equipment is sourced from trusted global manufacturers and delivered with full certification, compliance, and after-sales support.

🔸API 16A/16D compliant components

🔸Custom-configured for HPHT or standard rigs

🔸Full set including Annular, Ram, HPU, manifold & control panel

🔸Fast international delivery

🔸Spare parts & field support available 24/7

Powerful Design. Reliable Supply.

At SABA Drilling, we bring together the best in engineering, functionality, and global supply chain efficiency. As a trusted international supplier not a manufacturer we deliver certified, high-performance well control equipment, including complete BOP stacks, manifolds, and spare parts.

Our strength lies in strategic sourcing, fast logistics, and deep knowledge of operational field demands. Every item we supply is carefully selected to meet:

🔸Your Specs

🔸 Your Pressure Requirements

🔸 Your Deadline

🔸Complete BOP stacks (Annular + Ram)

🔸Diverter systems and Choke/kill manifolds

🔸API-compliant spares and redress kits

🔸Accessories: Bonnets, pistons, hydraulic seals, hoses & fittings

Total Reliability, Global Reach

At SABA Drilling, we specialize in sourcing and supplying certified well control components to drilling contractors and oilfield service companies across the globe. Whether it’s a BOP stack, control panel, or hard-to-find spare part, our global network ensures fast, traceable, and API-compliant delivery—wherever you operate.

We don’t manufacture; we strategically supply. With a focus on quality, availability, and long-term support, we give your operation the confidence it needs.