Ram Preventers Engineered to Seal. Built to Withstand.

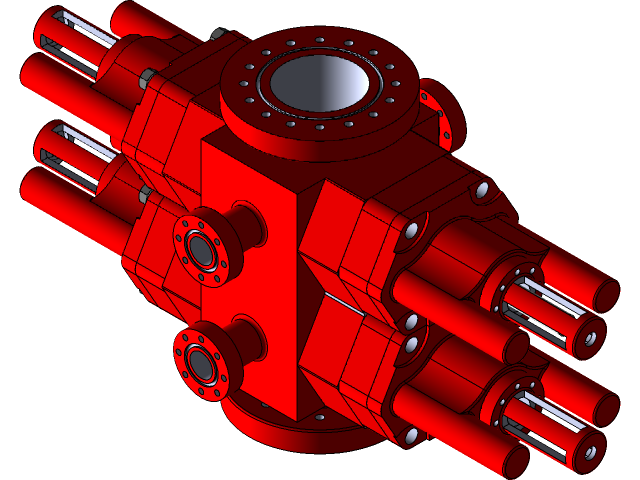

Ram-type blowout preventers are engineered for critical well control, designed to rapidly shut in the wellbore and isolate formation pressures in emergency conditions. At SABA Drilling, we supply high-integrity Ram Preventers that conform to API 16A and are trusted across both onshore and offshore drilling operations.

🔸 API 16A Certified Construction

Manufactured in compliance with API 16A and ISO 13533, ensuring full compatibility with international drilling standards and regulatory environments.

🔸 High-Pressure Rated Bodies

Available in pressure classes up to 15,000 psi, built from high-strength alloy steel with corrosion-resistant coatings for extended service life.

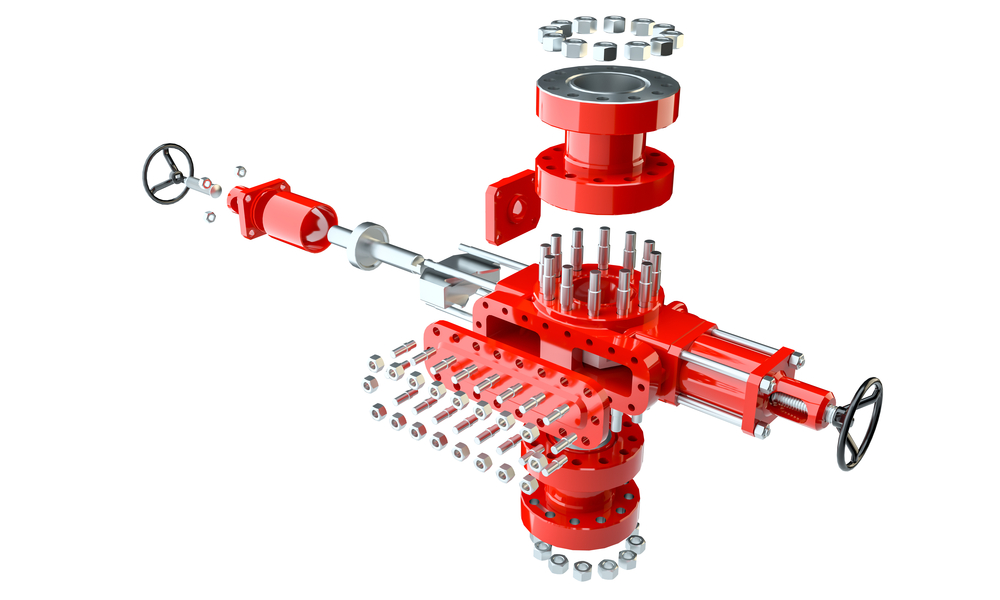

🔸 Hydraulic Actuation System

Fast and fail-safe ram closure via dual-acting hydraulic cylinders, ensuring reliable shut-in during well control incidents.

🔸 Multiple Bore Sizes Available

Standard sizes from 7-1/16″ to 21-1/4″, adaptable for various casing and tubing programs.

Ram Preventers Precision Under Pressure

Ram Preventers are the backbone of well control operations, engineered to perform reliably under high-pressure and high-risk conditions. At SABA Drilling, we supply API 16A-certified ram-type BOPs trusted across global drilling fleets for their sealing strength, structural integrity, and modular adaptability.

Whether your operation demands pipe rams, shear rams, or blind rams, our products are precision-machined and designed to integrate seamlessly with your existing BOP stack and control systems.

🔸API 16A / ISO 13533 Compliant Design

Full compliance with international well control standards.

🔸Multi-Ram Compatibility

Interchangeable shear, blind, and pipe rams for operational flexibility.

🔸High-Pressure Durability

Pressure ratings up to 15,000 psi with robust elastomer-metal sealing.

🔸Hydraulic Actuation System

Fast response time with dual-piston actuation for emergency shut-ins.

🔸Available Bore Sizes:

From 7-1/16” to 21-1/4” for various casing and tubing programs.

🔸Applications:

Onshore rigs, offshore platforms, HPHT wells, workover operations.

Total Well Control Begins with the Right BOP Stack

At SABA Drilling, we deliver API 16A-certified ram preventers engineered for high-pressure performance, rapid response, and long-term durability. Whether for land-based rigs or offshore platforms, our blowout preventers provide secure wellbore isolation in critical moments.

Each unit supports interchangeable shear, pipe, and blind rams, with hydraulic actuation and modular compatibility with global rig stacks. With bore sizes from 7-1/16″ to 21-1/4″, and pressure ratings up to 15,000 psi, our systems meet the demands of the most extreme drilling environments.

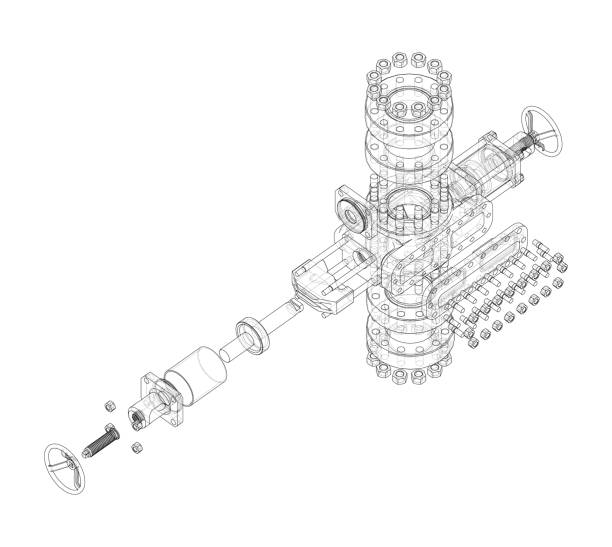

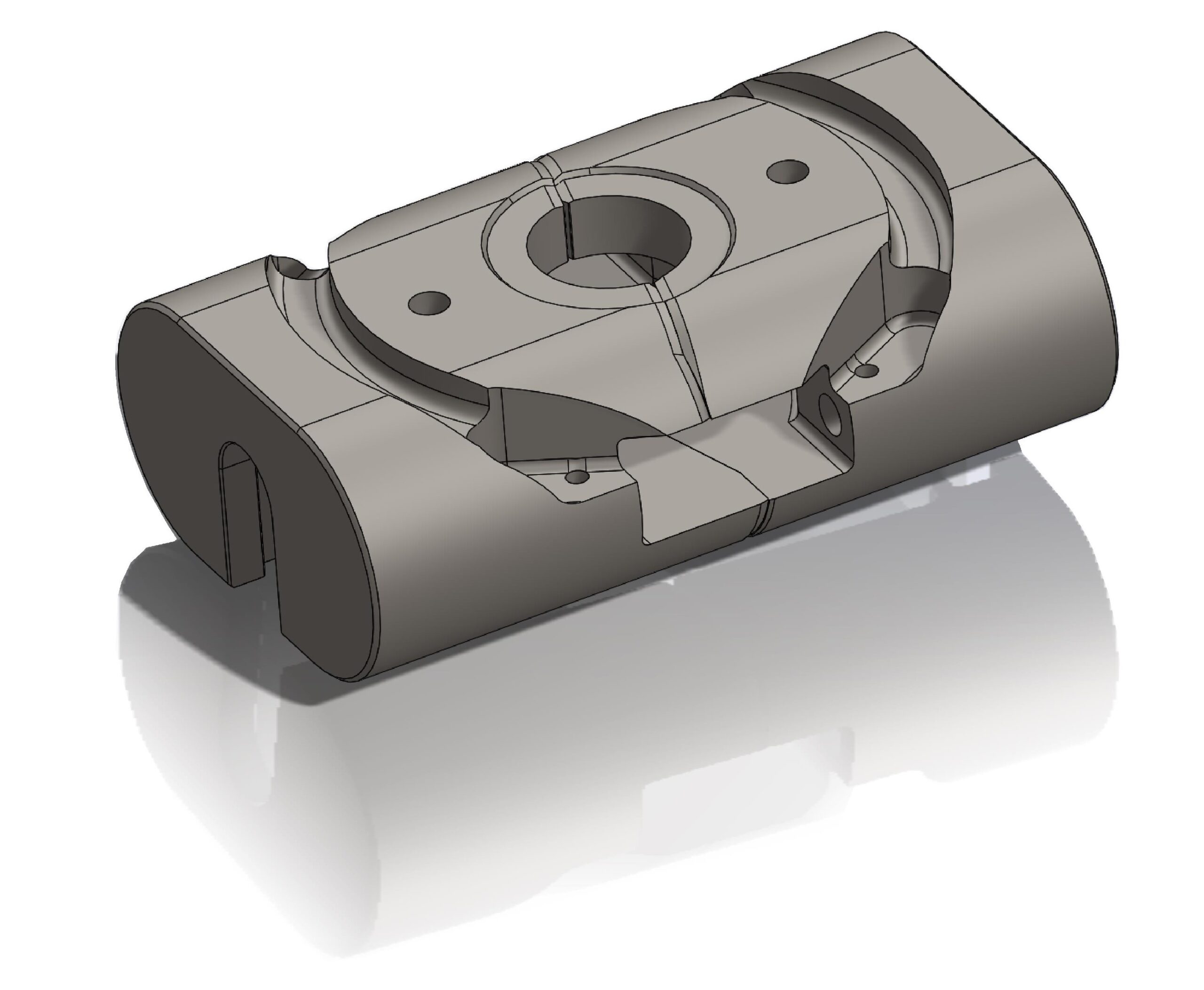

Precision-Machined Ram Blocks for Uncompromising Well Control

Manufactured from high-grade forged alloy steel and precision-machined for flawless sealing, our Ram Blocks are built to handle the most extreme well control environments. Each unit is designed for compatibility with major BOP systems and meets the performance expectations set by API 16A.

Whether your operation requires pipe rams, blind rams, shear rams, or variable bore configurations, SABA Drilling provides fully traceable, field-ready ram assemblies stocked and shipped globally.

🔸API 16A Certified.

🔸Available for all bore sizes (7-1/16″ to 21-1/4″).

🔸Built for shear, blind, pipe & VBR types.

🔸CNC precision + heat-treated durability.

🔸Rapid global delivery & support.

Advanced Ram Preventer Solutions Engineered for Critical Control

Ram-type Blowout Preventers are engineered to respond instantly to well control events, isolating pressure and containing formation influx with mechanical precision. At SABA Drilling, we offer a full line of API 16A-compliant Ram Preventers designed for both onshore and offshore drilling environments.

Our Ram BOPs are available in single, double, and quad configurations, with pressure ratings up to 15,000 psi and bore sizes ranging from 7-1/16″ to 21-1/4″. Interchangeable ram blocks—pipe, blind, shear, and VBR—allow for operational flexibility and fast adaptation to changing well conditions.

Precision-built. Rapid to deploy. Proven under pressure.

| Model | Bore Size (inches) | Pressure Rating (psi) | Application | Standards Compliance |

|---|---|---|---|---|

| RP-7 | 7/1/2016 | 5,000 | Onshore | API 16A |

| RP-11 | 11 | 10,000 | Onshore / Offshore | API 16A / ISO 13533 |

| RP-13.625 | 13-5/8 | 10,000 | Offshore | API 16A / ISO 13533 |

| RP-18.75 | 18-3/4 | 15,000 | Offshore HPHT | API 16A |

| RP-21.25 | 21-1/4 | 15,000 | Offshore HPHT | API 16A |

Where Engineering Meets Energy

At SABA Drilling, we believe that performance starts at the foundation with robust rigs, intelligent systems, and precision-engineered equipment designed to withstand the world’s most demanding oilfield conditions.

Our portfolio supports everything from deep onshore operations to high-pressure offshore environments, powered by a commitment to technical excellence, reliable logistics, and long-term client partnerships.

Wherever energy flows, SABA delivers.

Choke & Kill Manifolds Precision Control in Critical Moments

Our Choke and Kill Manifolds are engineered for absolute pressure management during well control operations. Designed in compliance with API 16C, these units regulate flow, minimize kick intensity, and enable secure circulation of kill fluids under extreme downhole conditions.

Each manifold is built from high-strength forged steel, equipped with manual or hydraulic gate valves, and customizable according to your rig’s layout—whether for land rigs, offshore jack-ups, or deepwater platforms.

🔸API 16C Certified

🔸Pressure rating: 5,000 / 10,000 / 15,000 psi

🔸Configurable standpipe arrangement

🔸Optional pressure gauges and safety relief systems

🔸Fast shipment and technical support available globally

Engineered to Perform. Designed to Withstand.

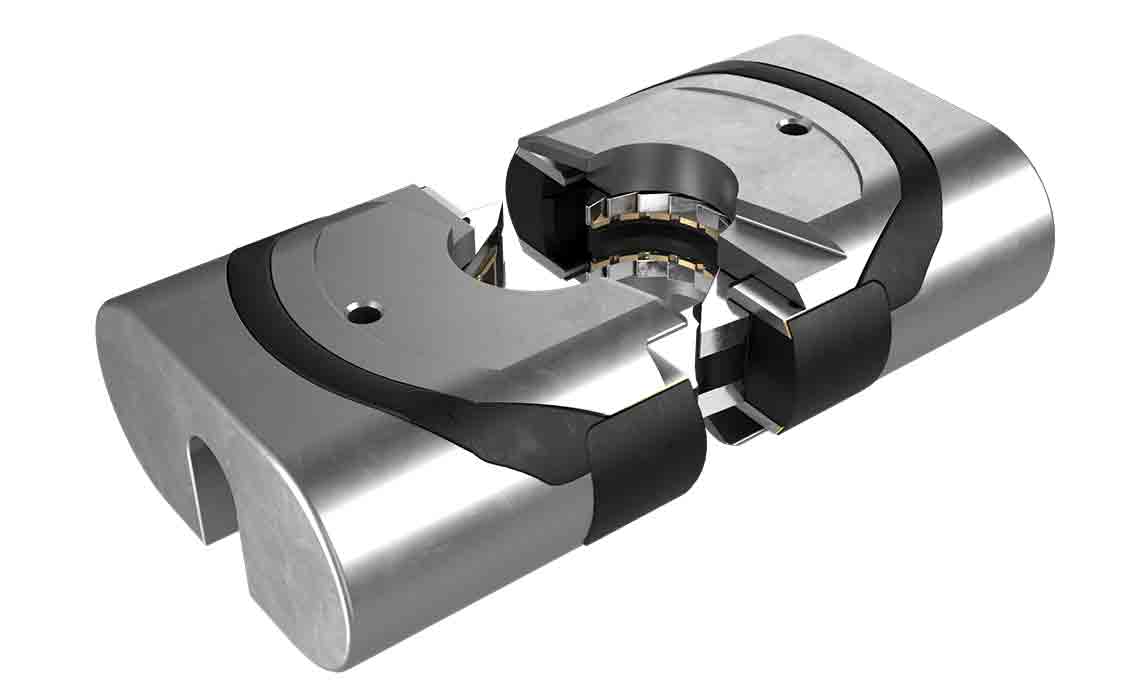

This is more than equipment—it’s engineered assurance. Our Ram Blowout Preventers represent the fusion of advanced metallurgy, modular design, and high-pressure sealing technology. Built in strict accordance with API 16A, each unit is validated through rigorous testing to ensure it performs when your rig demands it most.

Available in single, double, and quad configurations with rams that shear, seal, and isolate across a wide range of bore sizes, our BOPs are trusted by the world’s most demanding drilling operations.

From concept to casing, precision is in our DNA.

Modular Ram Blocks Designed to Adapt. Built to Seal.

SABA Drilling offers a complete lineup of Ram Block Assemblies, compatible with major BOP designs and certified to API 16A. Whether you need precision-sealing pipe rams, emergency-response shear rams, or flexible VBR (Variable Bore Rams), our modular units are engineered for high-pressure integrity and rapid deployment in critical situations.

Each ram is CNC-machined, heat-treated, and supplied with full traceability and materials certification. Designed for fast change-out and universal compatibility, our rams are in stock and ready to ship globally.

🔸API 16A & NACE MR0175 compliant

🔸Available in 7-1/16″ to 21-1/4″ bore sizes

🔸Optimized for Pipe / Shear / Blind / VBR

🔸Alloy steel bodies + wear-resistant inserts

🔸Custom elastomer options for HPHT service