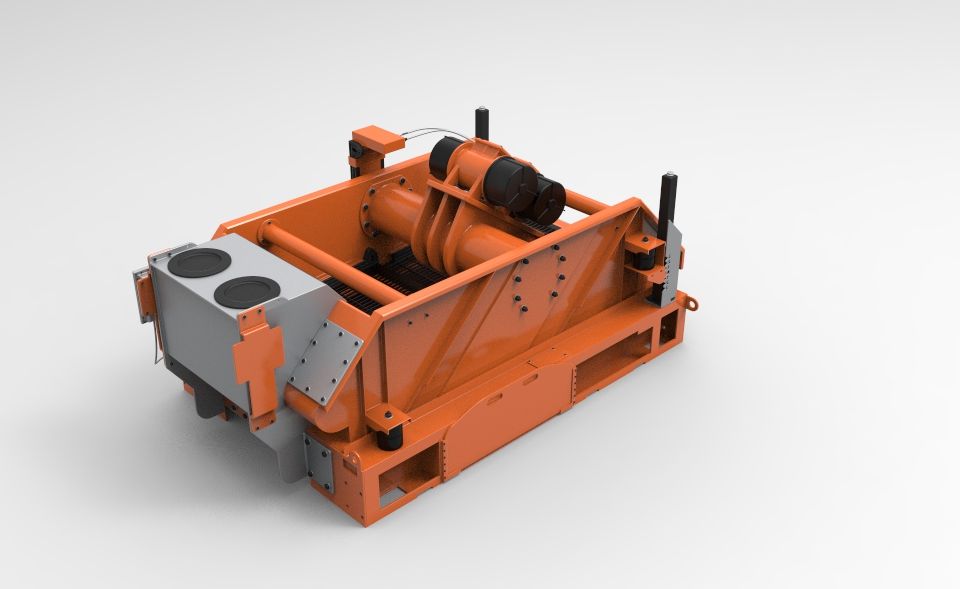

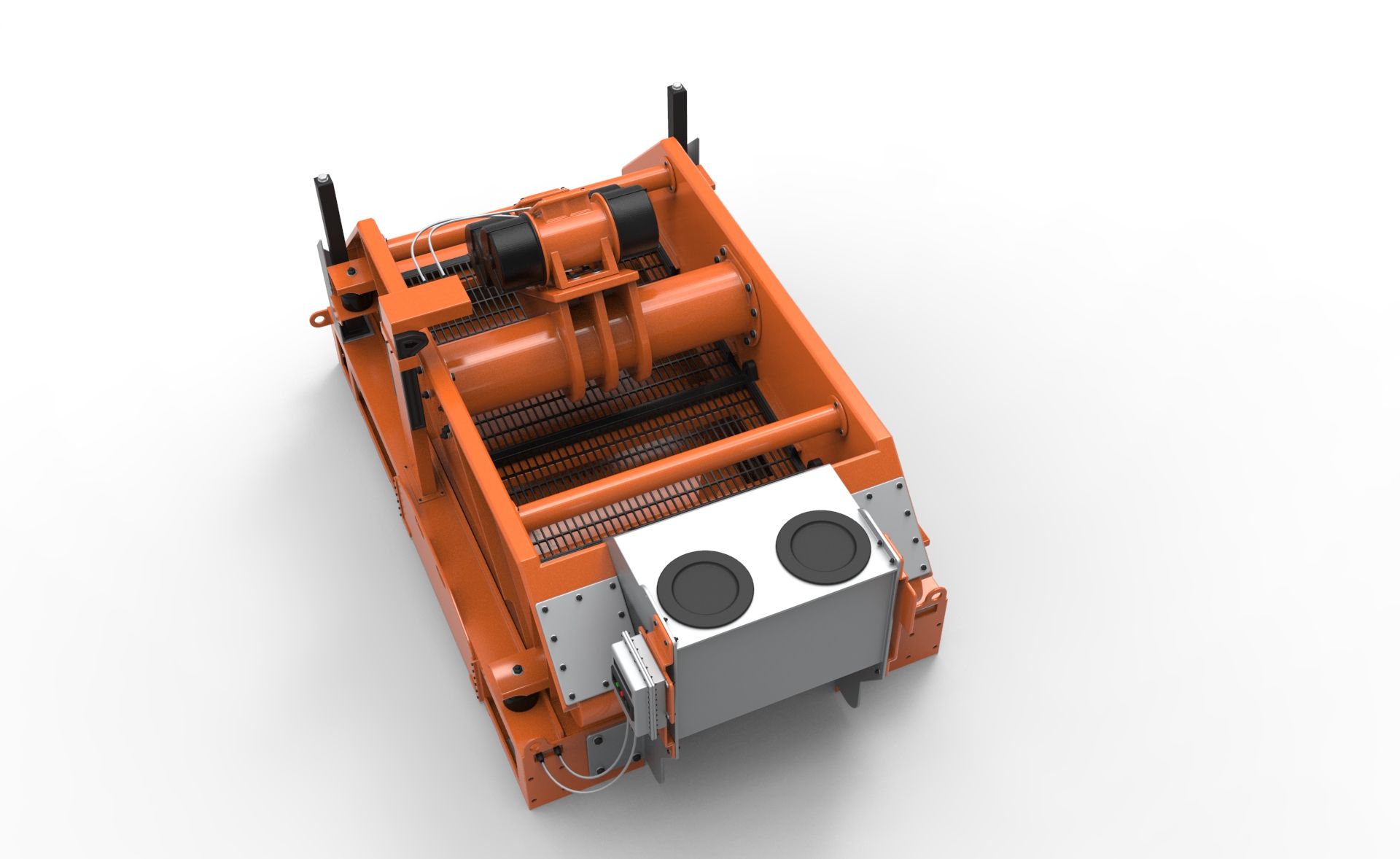

Global Supply of High-Performance Shale Shakers, Engineered for Efficiency

SABA Drilling proudly stands at the forefront of international equipment supply, delivering cutting-edge shale shakers to clients across the globe with a strong focus on high-demand markets in the Gulf region, Central Asia, and North Africa.

As a non-manufacturer global supplier, we source only from the most reputable OEMs worldwide, ensuring our clients receive equipment that meets or exceeds the latest API RP 13C, ISO, CE, and DNV standards. Our shale shakers are available in a wide range of motion types, screen areas, and mounting formats, adaptable to every rig condition from desert-based land rigs to offshore deepwater platforms.

We offer:

🔸 Technical precision: Equipment configurations tailored to specific drilling environments and flow conditions.

🔸 Commercial flexibility: Competitive pricing, multi-brand sourcing, and logistics coordination.

🔸 Operational reliability: Extended service life, reduced maintenance, and enhanced solids control.

🔸 Fast global dispatch: Strategic partnerships with international freight carriers for rapid delivery to any location.

🔸 Expert support: Pre-sale technical consultation, post-sale service coordination, and screen replacement solutions.

Our commitment goes beyond just supplying equipment we enable our clients to optimize drilling efficiency, reduce non-productive time (NPT), and extend the lifespan of their mud systems.

If your operation demands high-efficiency solids separation with proven reliability, SABA Drilling is your trusted supply partner.

| Category | Type | Deck Configuration | Capacity Range (GPM) | Typical Size (L×W×H in ft) | Compliance / Standard | Usage |

|---|---|---|---|---|---|---|

| Motion Type | Linear Motion | Single / Dual | 400 – 800 | 8×6×6 to 10×7×7 | API RP 13C, ISO 13501 | High-volume, fast solids removal |

| Balanced Elliptical | Dual / Triple | 300 – 700 | 9×6×7 to 11×7×7 | API RP 13C | Improved drying and lower G-force | |

| Circular Motion | Single | 200 – 400 | 7×5×6 | API RP 13C | Gentle solids removal, older rigs | |

| Dual Motion (Adjustable) | Dual | 400 – 900 | 9×6×7 to 11×7×8 | API RP 13C / CE Certified | Adaptive to fluid properties and formations | |

| Screen Area | Compact Shaker | Single Deck | 200 – 400 | 6×4×5 | API 60 – API 230 mesh | Small rigs or limited space |

| High-Capacity Shaker | Triple Deck | 700 – 1200 | 10×7×7 to 12×8×8 | API RP 13C / ISO Standards | Large rigs with high flow rate | |

| Mount Type | Skid-Mounted | Variable | — | Varies | API, CE | Onshore rigs |

| Trailer-Mounted | Variable | — | Varies | API | Mobile / workover rigs | |

| Offshore Modular | Compact | — | Modular | ABS / DNV | Offshore platforms |

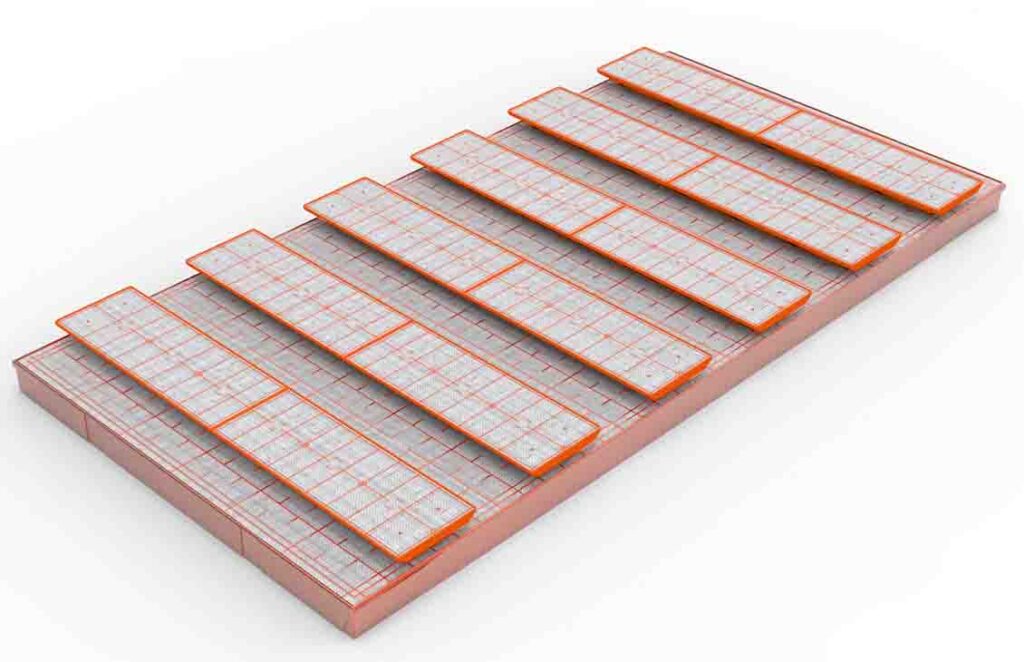

Premium Shale Shaker Screens for Demanding Operations

SABA Drilling supplies high-performance shaker screens engineered to meet API RP 13C standards and optimized for demanding drilling operations. From flat and pyramid to composite and soft mesh screens, we offer a full range of options tailored for land and offshore rigs.

🔸Full API designation coverage (API 20–325)

🔸Durable, corrosion-resistant multilayer designs

🔸Reliable delivery to Gulf and international markets

🔸Sourced from world-class OEMs

Our goal is to help drilling contractors reduce solids load, improve mud quality, and extend screen life without compromise.

| Screen Type | API Designation | Mesh Size (U.S.) | Typical Screen Layer | Application | Advantages |

|---|---|---|---|---|---|

| Flat Screen (PWP) | API 20 – API 325 | 20 – 325 | Single / Double | General drilling operations | Cost-effective, easy to install |

| Pyramid Screen | API 40 – API 270 | 40 – 270 | Double / Triple | High-flow systems, offshore rigs | Larger surface area, improved capacity |

| Hook Strip Screen | API 60 – API 230 | 60 – 230 | Single / Double | Older shale shakers, retrofits | Simple design, good for small rigs |

| Composite Screen | API 20 – API 325 | 20 – 325 | Multi-layered | High-efficiency shale shakers | Long life, corrosion-resistant, lightweight |

| Soft Mesh Screen | API 80 – API 200 | 80 – 200 | Single | Low-G shakers or sensitive formations | Flexible, reduces breakage, gentle cuttings removal |

Certified Shale Shaker Solutions Where Design Meets Global Standards

At SABA Drilling, we supply high-efficiency shale shaker systems and screens that seamlessly combine advanced engineering with full API RP 13C compliance. Our commitment to quality ensures that each unit we deliver performs reliably in the harshest drilling environments whether onshore or offshore.

As an international procurement partner not a manufacturer we’re uniquely positioned to offer multi-brand flexibility, fast logistics, and independent technical consultation. Our shaker systems are carefully selected from the most reputable OEMs around the world to meet the evolving operational and regulatory demands of today’s energy sector.

What We Offer:

Whether you need a full shaker package or a rapid screen replacement, SABA Drilling delivers equipment you can trust—backed by technical integrity and commercial strength.

🔸API Certified Equipment

All units conform to API RP 13C & ISO quality standards, ensuring full compatibility and traceability.

🔸Tailored Screen Options

From flat and pyramid screens to composite and soft mesh, we match the right screen to the right rig every time.

🔸Global Reach, Gulf Focus

With logistics hubs and freight partners across key ports, we ensure timely deliveries to any GCC country or beyond.

🔸Commercial Reliability

Transparent sourcing, stable pricing, and long-term supplier relationships safeguard your project schedule and budget.

🔸Technical Support

We provide screen consultation, shaker selection, and post-sale service coordination to reduce NPT and boost operational uptime.

Precision-Driven Solids Control for Modern Drilling

Our shale shaker solutions are engineered with a singular focus: to enhance performance, reduce solids load, and optimize mud recovery in every drilling condition. Whether operating in harsh desert environments or offshore platforms, SABA Drilling delivers screen technologies and shaker units built to exceed global performance standards.

With unmatched sourcing capability and technical know-how, we empower drilling contractors to operate more efficiently, reduce maintenance cycles, and extend equipment life.

Engineered Screens. Trusted Worldwide.

SABA Drilling delivers top-tier shaker screens designed to meet the highest standards of durability, filtration accuracy, and operational efficiency. Built for maximum separation with minimal maintenance, our screens are trusted by drilling operators across the Gulf and beyond.

Whether you’re operating in high-flow zones or managing sensitive formations, we supply screen solutions that are precision-matched to your shaker, your mud system, and your deadlines.

🔸API RP 13C Certified.

🔸 Available in Flat, Pyramid, Composite & Hook strip.

🔸 Wide mesh range: API 20 – API 325.

🔸 Rapid delivery across GCC & international locations.

about mi swaco

Enjoy the best design & functions combined together.

As a global leader in solids control and fluid management solutions, MI SWACO a Schlumberger company has set the industry standard for innovation, reliability, and performance. Their shale shakers, screens, and mud treatment systems are trusted by major operators across the world for delivering consistent results in the most demanding drilling environments.

At SABA Drilling, we are proud to collaborate with MI SWACO, supplying their premium equipment to our clients across the Gulf region and beyond. This partnership allows us to provide cutting-edge technology, backed by proven engineering and the global legacy of Schlumberger.