Built for Performance, Trusted Worldwide

Every mast we build reflects our commitment to strength, mobility, and safety. From modular single-pole structures to telescopic cantilever systems, our mast lineup supports various drilling environments with minimal downtime and optimal load distribution.

Engineered for efficient assembly and transport, our mast systems are trusted by operators across onshore fields and remote locations worldwide.

Precision-Engineered Mast Solutions

Our drilling masts are designed to meet the highest industry standards ensuring superior load capacity, structural integrity, and fast rig-up time. Built for durability and safety, each mast supports hook loads from 250,000 lbs to over 1,000,000 lbs, making them ideal for operations ranging from shallow workover to ultra-deep HPHT wells.

Whether you’re drilling in North America or the Middle East, SABA Drilling delivers reliable mast systems tailored to your project’s exact needs.

Structural Grades of Drilling Masts

At SABA Drilling, we classify our drilling masts based on hook load capacity, structure type, and operational requirements, ensuring clients receive the most reliable structure for their drilling environment. Each mast is built to meet or exceed API Spec 4F standards, with optimal safety, modular design, and ease of transportation and erection.

Type A – Standard Duty Mast

Designed for light operations and workover rigs, Type A masts support hook loads up to 250,000 lbs., with heights ranging from 80 to 110 ft. These are ideal for quick deployment and minimal site footprint.

Type B – Medium Duty Mast

Suited for shallow to mid-depth drilling, these masts carry 250,000 to 500,000 lbs hook loads and typically stand 110 to 130 ft tall. Featuring box-type or lattice structures, they balance strength and transportability.

Type C – Heavy Duty Mast

With hook load capacity between 500,000 and 750,000 lbs, and height ranges of 130 to 140 ft, these robust structures are widely used for medium to deep wells. Commonly used in land rigs across North America and the Middle East.

Type D – Extra Heavy Duty Mast

Built for demanding drilling projects, these masts support up to 1,000,000 lbs, and reach heights of 140 to 150 ft. Their lattice or cantilever designs allow for optimal weight distribution and rig floor flexibility.

Type E – Ultra Heavy Duty Mast

Ideal for high-pressure, high-temperature (HPHT) or deep-critical wells, these masts exceed 1,000,000 lbs hook load, and stand over 150 ft, with cantilever or telescopic structures for advanced operational control and enhanced safety.

| Classification | Type | Hook Load Capacity | Height (ft) | Structure Type | Common Use |

|---|---|---|---|---|---|

| Mast Type A | Standard | ≤ 250,000 lbs | 80 – 110 ft | Single-Pole | Light workover rigs |

| Mast Type B | Medium Duty | 250,000 – 500,000 lbs | 110 – 130 ft | Box Type / Lattice | Shallow to mid-depth drilling rigs |

| Mast Type C | Heavy Duty | 500,000 – 750,000 lbs | 130 – 140 ft | Box Type | Mid-depth to deep drilling |

| Mast Type D | Extra Heavy Duty | 750,000 – 1,000,000 lbs | 140 – 150 ft | Lattice or Cantilever | Deep oil and gas wells |

| Mast Type E | Ultra Heavy Duty | > 1,000,000 lbs | 150 – 180+ ft | Cantilever or Telescopic | HPHT wells, critical wells |

Our Strengths in Every Rig We Build

We deliver mast systems built to withstand extreme environments engineered for maximum durability and long-term performance under pressure.

Engineered Strength

We deliver mast systems built to withstand extreme environments engineered for maximum durability and long-term performance under pressure.

Global Standards

All our equipment is certified to meet or exceed API 4F and international oilfield standards, ensuring unmatched reliability worldwide.

Rapid Deployment

Our modular mast designs reduce rig-up time and logistics cost ideal for remote locations and fast-paced drilling projects.

Custom-Built Solutions

From shallow land rigs to HPHT operations, we tailor mast systems to meet the unique technical and operational needs of each client.

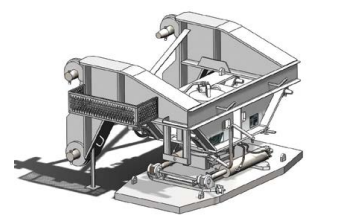

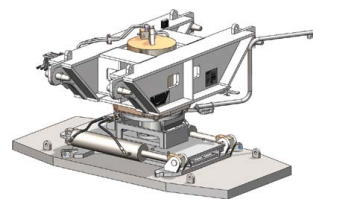

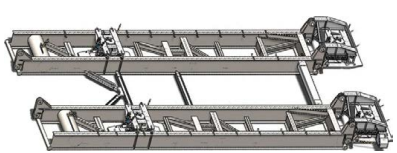

Smart Mechanics, Maximum Efficiency

At SABA Drilling, we engineer our pipe handling systems for flawless performance in high-demand drilling environments. Combining ergonomic design with precision hydraulics, our solutions increase crew safety and minimize rig downtime.

Whether onshore or offshore, experience smoother, smarter pipe movement every step of the way.

Power the Future with Us

Be part of a bold journey in drilling innovation. Joining only takes a minute success lasts much longer.