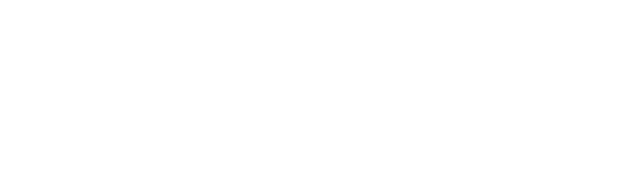

Precision-Engineered Swivel Systems designed in Every Detail

At SABA Drilling, we go beyond hardware we engineer reliability. Our Swivel & Hose Systems are designed using advanced CAD modeling and finite element analysis to ensure optimal stress distribution, maximum safety margins, and long-lasting field performance.

🔹Precision-manufactured for flawless hose articulation.

🔹Sealed bearing design for smooth rotation under high load.

🔹API 8C and 7K certified to ensure global compatibility.

🔹Built for harsh desert rigs and offshore platforms alike.

Whether you’re planning a new rig setup or replacing legacy systems, SABA’s engineering-driven solutions deliver performance that never quits.

Designed with purpose. Built with precision. Trusted in every rotation.

High-Pressure Rotary Hoses Engineered for Performance in Motion

At SABA Drilling, we offer premium-grade Rotary Hoses (Kelly Hoses) built to perform under extreme dynamic loads, high-pressure fluid circulation, and continuous rotational movement. Designed to comply with API Spec 7K, our hoses deliver exceptional flexibility, burst resistance, and operational longevity.

🔹Available in 2″ to 3″ I.D. and lengths up to 60 ft.

🔹Working pressure: up to 7,500 psi, burst up to 15,000 psi.

🔹End fittings: NPT, Hammer Union, FIG 602 / 1002, API 6B.

🔹Reinforced with multi-layer high-tensile steel wire braids.

🔹Internal lining options: Nitrile, Neoprene, Viton.

🔹Temperature rating from –40°F to +250°F.

🔹API 7K / CE / ISO certified for worldwide drilling operations.

Designed for both land and offshore rigs, these hoses ensure safe and leak-free performance from the swivel to the standpipe keeping your rig running under pressure.

| Size (ID) | Length (ft) | Working Pressure (psi) | Burst Pressure (psi) | End Fittings | Lining Type | Reinforcement | Temp Range (°F) | Standards |

|---|---|---|---|---|---|---|---|---|

| 2" | 30 | 5,000 | 10,000 | 2" NPT / Hammer Union | Nitrile Synthetic | Multiple Steel Wire Braids | -20 to +200 | API Spec 7K |

| 2½" | 30–40 | 5,000 | 10,000 | 2½" FIG 602 | Neoprene / EPDM | Spiral-Wrapped High-Tensile | -30 to +220 | API Spec 7K / ISO |

| 3" | 30–60 | 7,500 | 15,000 | 3" FIG 1002 / API 6B | Viton Optional | 4–6 Layers Steel Wire | -40 to +250 | API 7K / CE Marked |

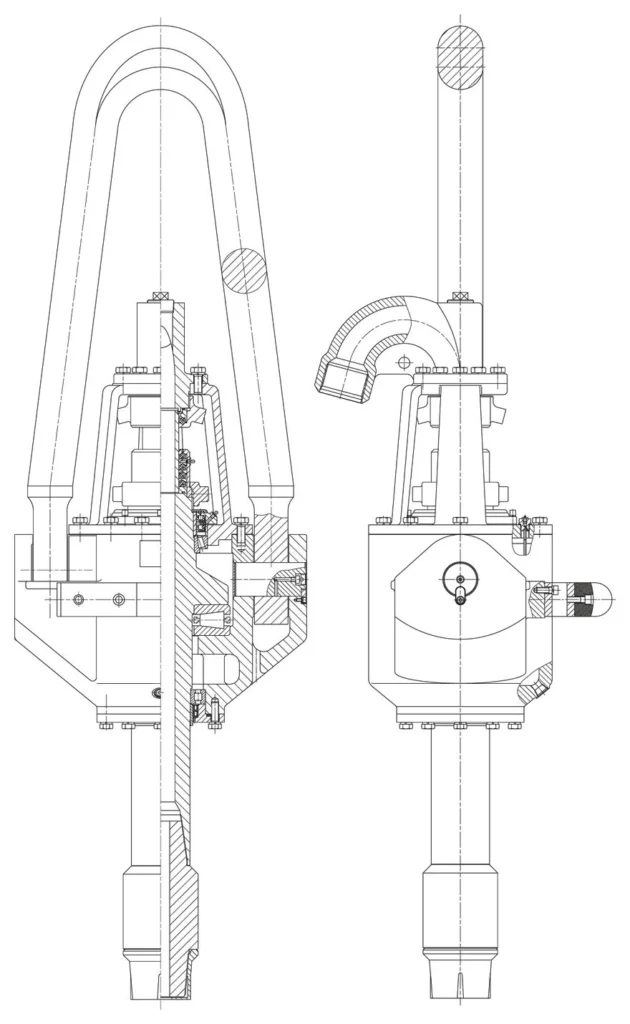

Swivel Assembly Built to the Core

Every component inside our Swivel Assemblies is designed for durability, precision, and high-pressure operation. The exploded view showcases our engineered internals, featuring:

🔹High-grade steel body housing.

🔹Precision bearings for rotational efficiency under load.

🔹Sealed washpipe and packing for zero-leak fluid transmission.

🔹Gooseneck connection with reinforced threading.

🔹Field-replaceable parts for ease of maintenance.

Each part meets API 8C / API 7K specifications and is 100% inspected before shipping.

Whether you’re performing rig upgrades or full assembly replacements, trust SABA Drilling to deliver performance from the inside out.

| Model | API Rating | Working Pressure (psi) | Bore Diameter (in) | Gooseneck Connection | Thread Type | Bearing Type | Grease System | Standard Compliance |

|---|---|---|---|---|---|---|---|---|

| SW-500 | API 8C | 5,000 | 3" | 4" API Reg LH | NC50 | Dual Roller + Thrust | Manual or Auto | API Spec 8C / 7K |

| SW-750 | API 8C | 7,500 | 3½" | 4½" API Reg LH | NC50 / 5½ FH | Sealed Taper Roller | Pressure-Lubricated | API Spec 8C / ISO |

| SW-1000 | API 8C | 10,000 | 4" | 5½" API Reg LH | 6⅝ Reg | High-Capacity Roller | Circulating Grease Pump | API 8C / ABS / DNV |

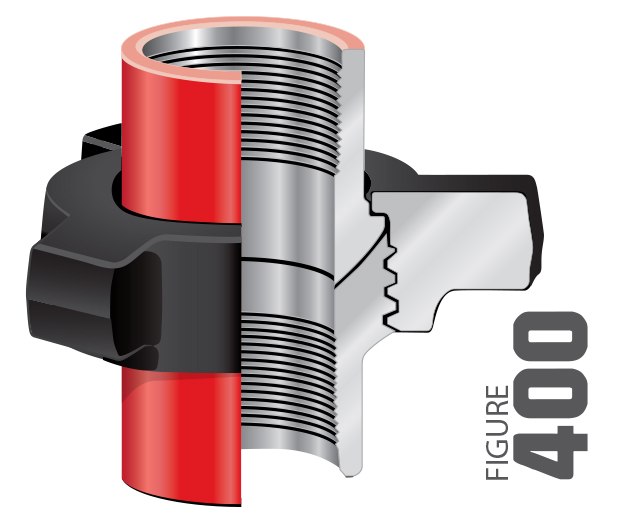

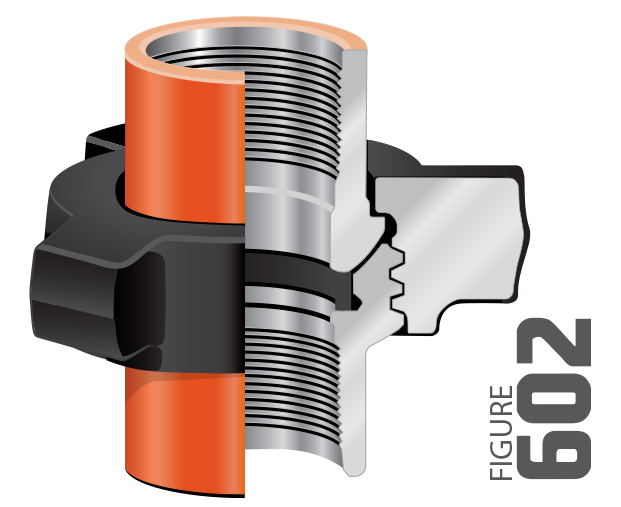

Hammer Unions Identify. Connect. Seal Under Pressure.

At SABA Drilling, we offer a full line of Hammer Unions in various pressure classes and connection sizes, each engineered for reliable sealing under demanding drilling, production, and stimulation environments. Our color-coded design follows industry standards for quick visual identification and pressure rating.

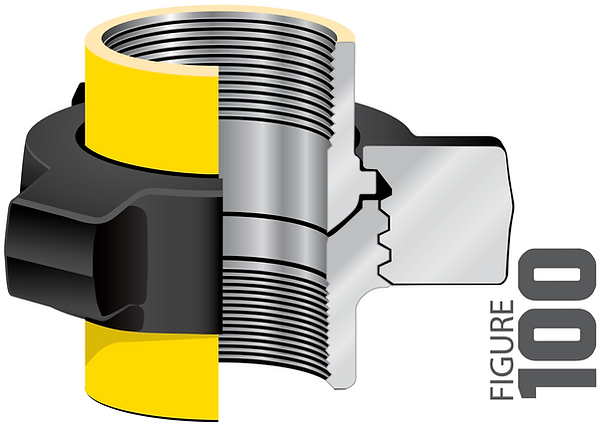

🟡 Figure 100 – 1,000 psi – General service, air & water.

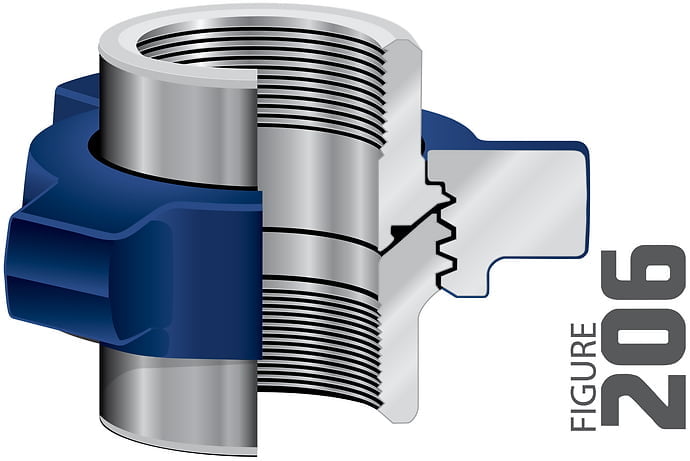

🔵 Figure 206 – 2,000 psi – Mud suction and cementing.

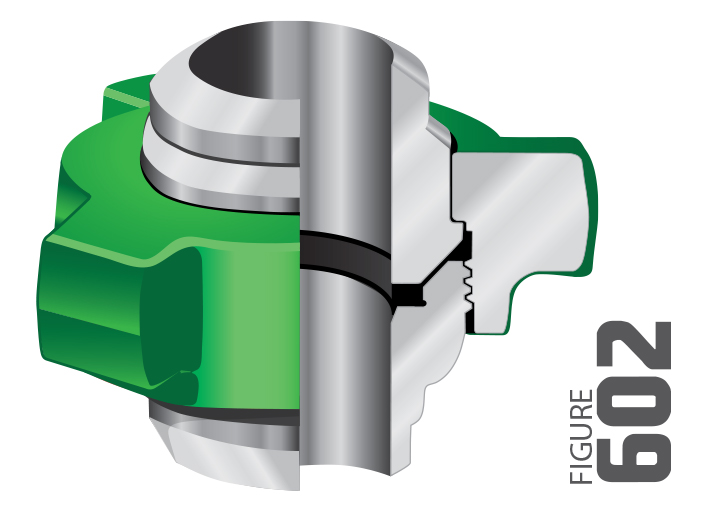

🟠 Figure 602 – 6,000 psi – High-pressure drilling fluids.

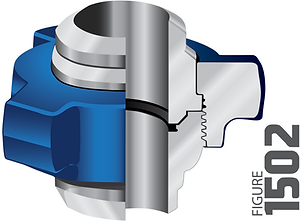

🔴 Figure 1502 – 15,000 psi – Frac, kill line, and acidizing.

⚫ Figure 400 – 4,000 psi – Well service, moderate pressure.

🟢 Figure 602 H2S – Sour gas-compatible, elastomer-sealed.

Built from forged alloy steel and precision-machined to API 6A / 16C or NACE MR0175 specs, our hammer unions are made to last, even in sour service and extreme thermal cycles.

Threaded, butt-weld, and flanged options available to suit any operation.

| Figure # | Size Range (in) | Pressure Rating (psi) | Seal Type | Material Class | Color Code | Typical Use | Standard |

|---|---|---|---|---|---|---|---|

| 100 | 1" – 4" | 1,000 | Metal-to-Metal | ASTM A105 | Gray | Low-pressure suction & discharge lines | API 6A |

| 200 | 1" – 4" | 2,000 | Metal-to-Metal | ASTM A105 | Blue | General service, air, water, oil | API 6A |

| 206 | 2" – 4" | 2,000 | Nitrile Rubber Seal | ASTM A105 | Blue with Nut | Mud suction, cement service | API 6A / ISO |

| 602 | 1" – 4" | 6,000 | Nitrile Rubber Seal | ASTM A105 | Red | High-pressure mud and manifold systems | API 6A / 16C |

| 1002 | 2" – 4" | 10,000 | Lip Seal (H2S Optional) | ASTM A105 | Orange | Choke & kill lines, well test, acidizing | API 16C / NACE MR0175 |

| 1502 | 2" – 4" | 15,000 | Lip Seal + Backup | ASTM A105 / SS | Red / Yellow | Frac service, extreme pressure flowlines | API 16C / Sour Gas |

Rotary Swivels Certified. In Stock. Delivered Worldwide.

At SABA Drilling, we understand that in the oilfield, downtime is not an option. That’s why we maintain a ready inventory of API 8C certified Rotary Swivels, available for immediate dispatch from our regional hubs in Houston, Dubai, and Dammam.

Our rotary swivels are manufactured to meet or exceed API 8C and API 7K standards, ensuring maximum safety, performance, and durability under harsh drilling environments. Whether you’re sourcing for rig-up projects, emergency replacements, or long-term tenders, we are your trusted procurement partner.

🔹Working pressure: 5,000 / 7,500 / 10,000 psi.

🔹Bore sizes: 3” to 4½”.

🔹Connections: 4″ API Reg LH / NC50 / 6⅝ Reg.

🔹Materials: High-strength alloy steel body, gooseneck, and wash pipe.

🔹Lubrication: Pressure-fed or grease-lubricated

🔹Seal type: Nitrile, Viton, or metal-to-metal available.

🔹Optional: Sour-gas service, low-temperature packing, field-repair kits.